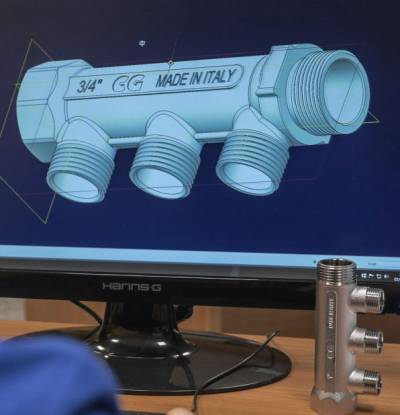

Design

Efficient and optimized processes

The mold is designed in cooperation with the customer, who sends us the drawing, and we transfer it inside our machining center, which, since 2016, has improved by introducing CAD CAM software. Software that makes processes more efficient and optimized.

Customer-friendly experience

By designing and having a continuous collaboration with the customer, our company allows the customer to have a tailor-made experience and, by producing everything in-house, guarantees 100% Made in Italy quality. This is one of the characteristics that allows us to collaborate with the most renowned companies in the plumbing and heating industry.

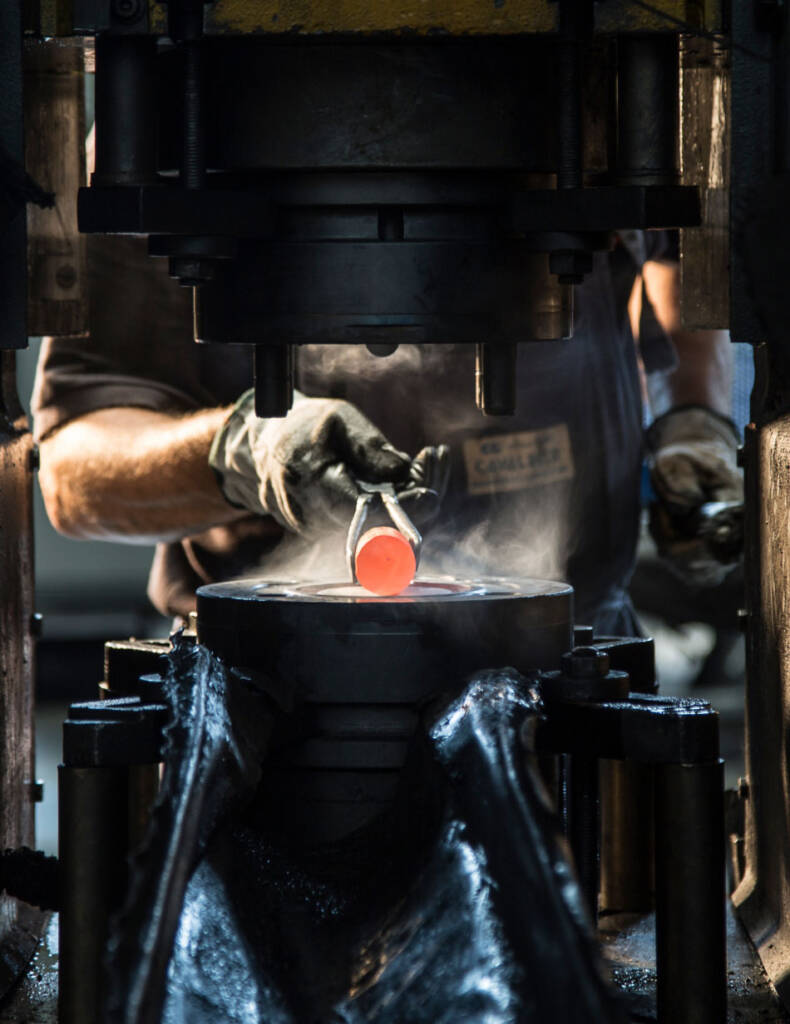

Hot molding

Some parts of the mold are essential to be heat-treated to improve the characteristics. In order to shape the metal parts, we have 20 state-of-the-art hot stamping presses that give our company a high production capacity, also enabling the manufacture of products tailored to the customer’s needs.

20

Latest generation stamping presses

The plusses of molding

Unlike other companies that rely on subcontractors, at CG Cavaletto we decided to introduce this department in-house because:

Cuts down processing time

Allowing parts to be made as they are made without having to wait to accumulate a minimum batch size to send to the supplier.

Lowers costs

Cancels transportation costs.

Lowers risk

Eliminates the risk of losing processed seeds in transport and having to start work from the beginning.