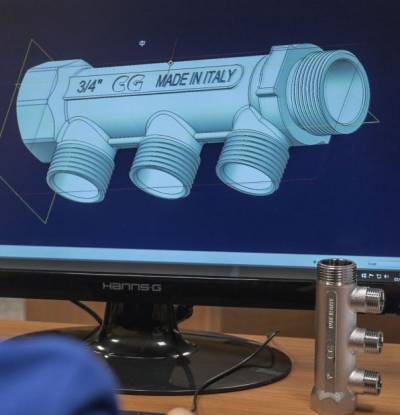

Component study

Before starting mass production that is optimal and successful, the customer sends our professionals the drawing of the component they want and we transfer it within our three-dimensional modeling software, so we create a collaboration between our customers and the professionals within the company.

The customer feels involved in the design of the “tailor made” component, and the professionals are facilitated to finalize a product that meets 100% of the requirements.

Prototype development

To be sure that the design is excellent, prototyping is necessary.

It involves verifying whether the component works with respect to:

01. the context in which it will work

02. to the actual needs of the customer

Mold design

To print the quality that each of our customers deserves, our work underwent a change in 2016 by introducing a new machining center aimed at optimizing processes.

We moved from just using 3D drawing to implementation with CAD – CAM software, generating tool paths of our 3- to 5-axis CNC machines.